The tube is particularly suitable for single-sideband and linear amplifiers.

| GENERAL DESCRIPTION |

|

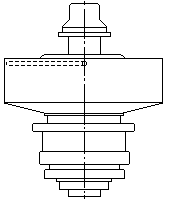

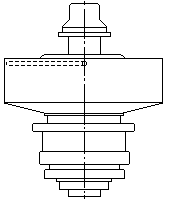

The RS 1072 C / FU115F is a forced air-cooled, metal-ceramic tetrode for frequencies up to 300 MHz, output power approx. 1 kW. The tube is particularly suitable for single-sideband and linear amplifiers. |

|

| TECHNICAL SPECIFICATIONS | ||||

| HEATING | ||||

| Heater voltage | 3.8 V ±5% | |||

| Heater current | 20.5 ±2 A | |||

| Preheating time | > 3 min | |||

| Type of heating | indirect by ac or dc | |||

| Cathode | matrix oxide | |||

| CHARACTERISTICS | ||||

| μ-factor of grid 2 | ±11 | |||

| Transconductance | ±43 mA/V | |||

| CAPACITANCES | ||||

| min | nom | max | ||

| Cathode/grid 1 | 32 | 36 | 39 | pF |

| Cathode/grid 2 | 1.2 | 1.5 | 1.8 | pF |

| Cathode/plate | 0.015 | pF | ||

| Grid 1/grid 2 | 50 | 57 | 65 | pF |

| Grid 1/plate | 0.15 | pF | ||

| Grid 2/plate | 12 | pF | ||

| Specifications may change without notice | ||||

| THIS TUBE IS USED IN THE FOLLOWING SHORTWAVE BROADCAST TRANSMITTERS | ||

| Manufacturer | Transmitter specifications | Power in kW |

| RIZ Transmitters | OR 50 K-01/A | 50 |

| OR 100 K-01/A | 100 | |

| Siemens | WR Send 50 K-04 | 50 |

| WR Send 100 K-04 | 100 | |

| THIS TUBE IS AVAILABLE FROM | ||

| Manufacturer | Rebuilder | Distributor |

| Xuguang | Kennetron | |

| PRICE LEVEL (US$) | |||||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 0 - 10 | 10 - 100 | 100 - 1000 | 1000 - 10,000 | 10,000 - 50,000 | 50,000 - 100,000 |